Commonly used valve body material code description

Valve body material code description:

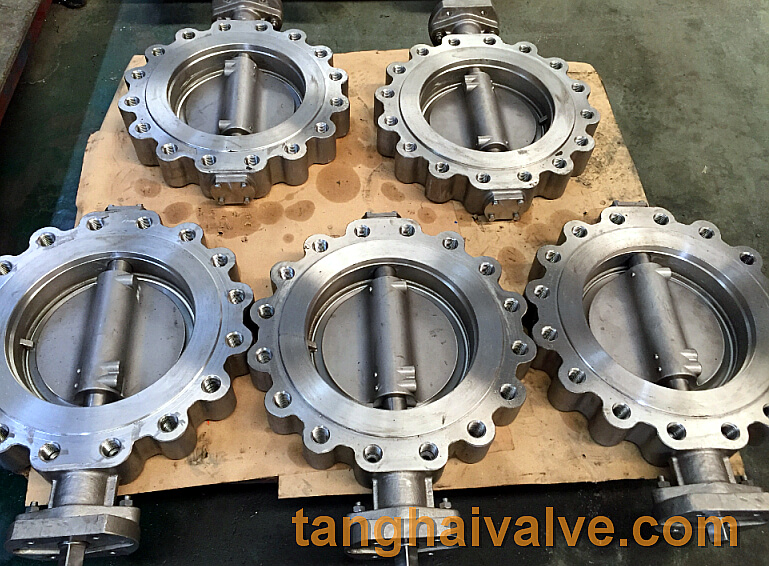

lug type butterfly valve body

The material of the valve body should first consider the physical properties (temperature, pressure) and chemical properties (corrosiveness) of the working medium. At the same time, you should also understand the cleanliness of the medium (with or without solid particles). In addition, it is necessary to refer to the relevant regulations and requirements of the country and the user department. Different valve body materials can meet the requirements of the valve in a variety of different working conditions. Correct and reasonable selection of valve materials can obtain the most economical service life and best performance of the valve.

| code | valve body |

| Z | grey cast iron |

| T | copper and copper alloy |

| C | carbon steel |

| K | Malleable cast iron |

| Q | ductile cast iron |

| I | Chrome-molybdenum steel: 1Cr5Mo ZG1Cr5Mo |

| P | 18-8series SS: Cr18Ni9Ti, ZG1Cr18Ni9Ti |

| R | 1Mo2T series SS: Cr18Ni12Mo2Ti, ZG1Cr18Ni12Mo2Ti |

| V | Chrome Molybdenum Vanadium Steel:12Cr1Mo1V, ZG12Cr1Mo1V |

| S | plastic |

| L | aluminium alloy |

| H | Cr13 series SS |

| A | Titanium and Titanium alloy |

Note: Gray cast iron valves with Pg≤16kgf/cm2, carbon steel valves with Pg≥25kgf/cm2, omit this code. Different valve models are suitable for different pressure levels. Therefore, when selecting the valve body material, the valve body material suitable for the working conditions should be determined according to different uses and different pressure levels.

Related products: wafer butterfly valve; lug butterfly valve; double flange butterfly valve;

Double eccentric butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.