Why is austenitic stainless steel magnetic

In the procurement case of austenitic stainless steel butterfly valves or gate valves, we can often find an interesting phenomenon. Customers carry magnets with them to check whether the material of the product is genuine. I think it is really “stainless steel” if it can’t be absorbed, and it’s faked with “stainless iron” if it sucks. This is really an “unjust case”. Today this article will share the unscientific aspects of this method.

high performance-double eccentric-butterlfy valve-wafer-lug-flanged (5)

The main reason for the emergence of the magnet inspection method is the recognition of a characteristic of austenitic stainless steel, that is, everyone must know that austenite is non-magnetic or weakly magnetic, while martensite or ferrite is magnetic. . Stainless steel is classified according to its organizational structure at room temperature: 1. Austenite type: such as 304, 321, 316, 310, etc.; 2. Martensite or ferrite type: such as 430, 420, 410, etc.; however, everyone ignores the change in ferrite content caused by the difference in forging and casting processes. This kind of magnetism, which is caused by chemical composition fluctuations or different processing conditions caused by smelting, cannot be regarded as counterfeit or substandard. Let’s see why?

1. During smelting, if composition segregation or improper heat treatment, a small amount of martensite or ferrite structure will appear in austenitic stainless steel. In this way, the austenitic stainless steel gate valve will have weak magnetism.

2. After austenitic stainless steel is cold-worked, the structure will also be transformed into magnetic martensite. The greater the degree of cold-working deformation, the more martensite transformation and the greater the magnetic properties of the steel.

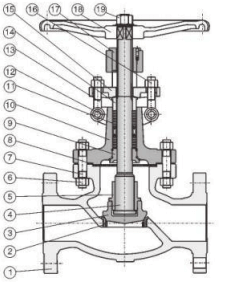

marine valve; butterfly valve; check valve; gate valve; manufacturer in China

3. When polishing the product, use an iron wrist to polish it. If it is not cleaned or there are iron filings on the surface, it will show magnetism.

However, the magnetism of austenitic stainless steel caused by the above reasons is not at the same level as that of other stainless steels, such as 430 and carbon steel. That is to say, even if austenitic steel shows a certain degree of weak magnetism, it makes the magnet feel When it comes to suction, it is by no means strong magnetism, and the product itself is still qualified. In other words, if the austenitic stainless steel gate valve is weakly magnetic or non-magnetic at all, it should be judged as 304 or 316 austenitic stainless steel. If the magnetism is the same as that of carbon steel and shows strong magnetism, the product material is not austenitic steel but other materials are used indiscriminately.

If manufacturers want to completely eliminate the magnetic properties of austenitic stainless steel caused by the above reasons, they can restore and stabilize the austenitic structure through high-temperature solution treatment, thereby eliminating the magnetic properties. At the same time, select sand with high silicon content during forging and polishing treatment and then pickling passivation to remove magnetism. At the same time, as a user, when we are purchasing, we also recommend to choose products from reputable manufacturers, not to be greedy for cheap prices and avoid being deceived.

Therefore, it is unscientific to use a magnet to detect whether austenitic stainless steel contains magnetism.

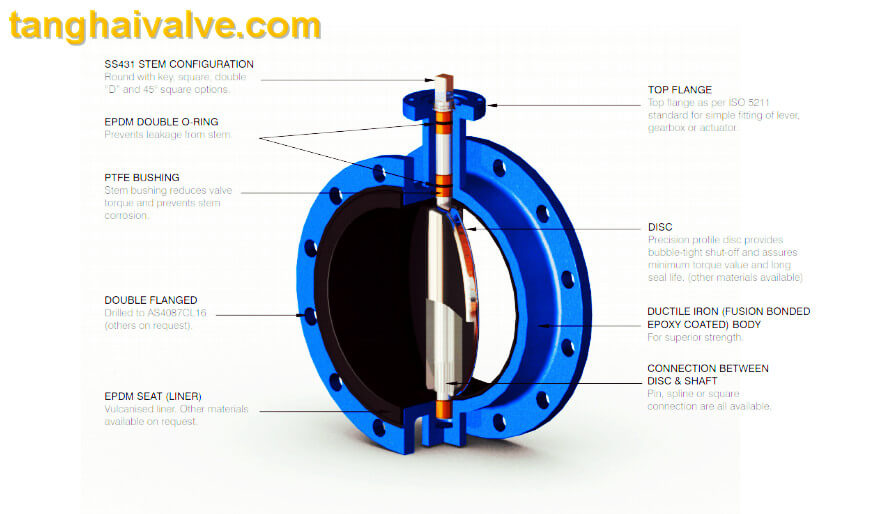

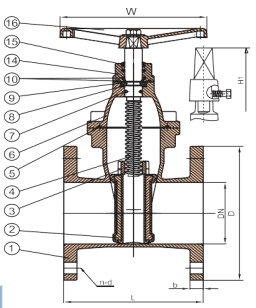

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Gate valve has a broad market in the field of sewage treatment

Features of Stainless Steel Valves

The difference and application of stainless steel 430, 304, 316

Operation precautions of stainless steel butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.