Selection Standard and Application Analysis for Marine Valve

Choosing the right valves for marine systems is crucial to ensure safety, reliability, and long-term performance in harsh offshore environments. Key selection criteria include:

1.1 Material Selection

Preferred Material: SS316, Duplex Stainless Steel, Bronze

Reason: High corrosion resistance in seawater, brine, and aggressive chemicals

Tip: Avoid carbon steel for exposed or submerged applications

1.2 Valve Type Selection

| Valve Type | Typical Marine Application |

| Butterfly Valve | Ballast systems, cooling water lines |

| Check Valve | Pump discharge, bilge lines, fire systems |

| Gate Valve | Seawater intake, cargo pipelines |

| Globe Valve | Flow regulation in steam or fuel systems |

| Ball Valve | Quick shut-off for fuel, oil, or air lines |

1.3 Standards & Classification

Ensure compliance with IMO, IACS, and classification societies such as:

DNV, ABS, LR, BV, CCS

Check for Fire-Safe, DNV-GL approved, or ISO/ANSI certified valves where required

1.4 Functional Requirements

Operating pressure & temperature

Flow direction and velocity

Manual, pneumatic, or electric actuation

End connection (flanged, wafer, threaded)

2. Application Analysis – Where Marine Valves Are Used

2.1 Engine Room Systems

Seawater cooling lines

Fuel oil, lubricating oil pipelines

Steam and condensate systems

Bilge and ballast systems

2.2 Deck Systems

Cargo handling valves

Firefighting systems

Air vent check valves for tanks

2.3 Underwater / Hull Applications

Seachests

Overboard discharge valves

Bottom inlet valves

Note: Corrosion resistance and class approval are critical here

3. Additional Recommendations

Use soft-sealing valves (e.g., EPDM-lined butterfly valves) for low-pressure, non-critical lines

Use metal-seated valves for high-temperature or abrasive media

Choose compact wafer-type valves to save space in narrow engine rooms

Plan for easy maintenance access, especially in engine room clusters

Ensure spare part availability for long-term operation at sea

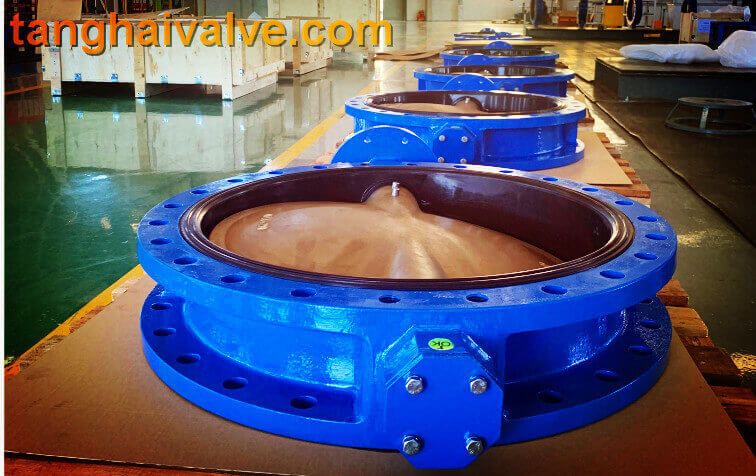

Tianjin Tanghai Valve Co., Ltd. is a professional marine valve manufacturer, including butterfly valve, check valve, gate /Knife gate valve. We have certificates: CE, ISO, BV, DNV foundry and products approval. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services. Below is our wafer butterfly valve of marine valves,if you need to check more information, please click here:https://www.tanghaivalve.com/wafer-type-butterfly-valve-th-btv-aw/.

Please contact us if you need more support, please contact us freely: info@tanghaivalve.com.

We are committed to “Build a top valve enterprise; Be a reliable partner!”Friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.