The principles and difference between one-way valve and check valve

One-way valve is sometimes called a check valve. One-way valve is a device in which fluid can only flow along the

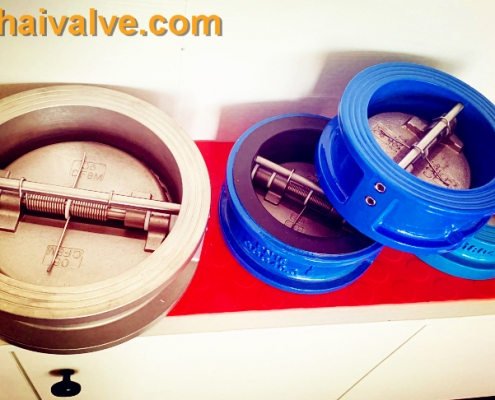

double-wing-check-valve-3

water inlet, but the medium at the outlet cannot flow back. The function of the check valve is to prevent the medium in the pipeline from flowing back. So what is the difference between the two? What is their working principle? Now, Mr. Harry Li from Tanghai Valve will give you a detailed introduction.

The difference between one-way valve and check valve:

One-way valve is a control type One-way valve, and check valve is a non-control type One-way valve. That is: One-way valve is used to provide pressure, and its main function is to maintain pipeline pressure. Although the check valve can also provide this function, it is mainly used to control the return of the medium and does not require pressure. That is: One-way valve has a tendency to control, and check valve is purely natural.

One-way valve means that the fluid can only flow along the water inlet, but the medium at the outlet cannot flow back, commonly known as the One-way valve. One-way valve is a check valve. The installation position of a swing check valve is not restricted. It is usually installed in a horizontal pipeline, but it can also be installed in a vertical pipeline or a dumping pipeline. When installing a check valve, pay special attention to the flow direction of the medium. The normal flow direction of the medium should be consistent with the arrow direction indicated on the valve body, otherwise the normal flow of the medium will be blocked. The bottom valve should be installed at the bottom of the pump suction line. When the check valve is closed, water hammer pressure will be generated in the pipeline. In severe cases, it will cause damage to the valve, pipeline or equipment, especially for large-mouth pipelines or high-pressure pipelines. Therefore, it should cause high attention of the check valve selection. . The check valve is only a one-way opening and closing valve that prevents the backflow of fluid media on various pipelines or equipment.

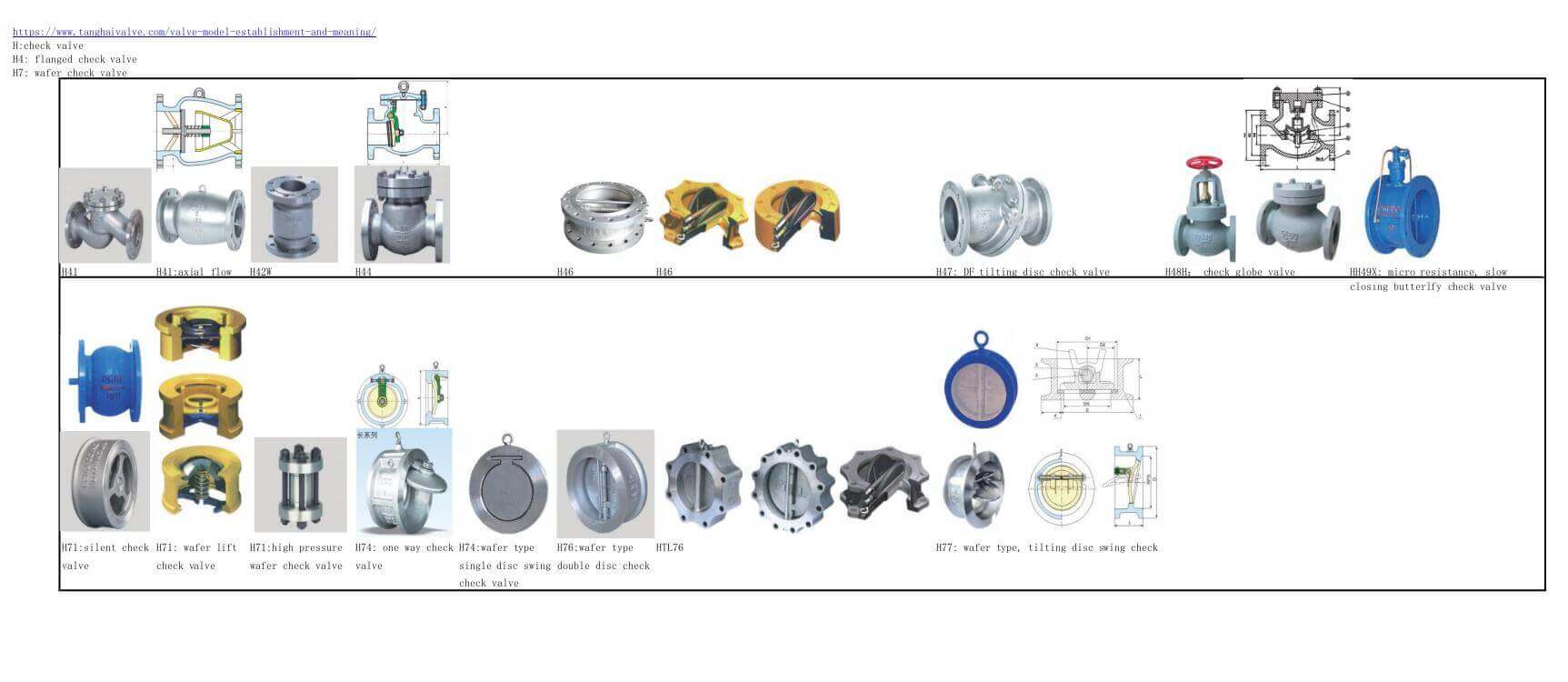

all types of check valve and structures -code names-photos

1. One-way valve: It is a typical seat valve, One-way valve, also known as check valve or check valve. Used in hydraulic systems to prevent reverse flow of oil flow.

One-way valve has two types: straight type and right angle type. The straight-through One-way valve is installed on the pipeline with a threaded connection. Right-angle One-way valve has three forms: thread connection, plate connection and flange connection. The hydraulically controlled One-way valve is also called a lock valve or a pressure holding valve. It is the same as the One-way valve to prevent the reverse flow of oil. However, when the oil flow is required to flow in the reverse direction in the hydraulic circuit, the oil pressure can be controlled and the One-way valve can be opened so that the oil flow can flow in both directions. The hydraulically controlled One-way valve uses a tapered valve core, so the sealing performance is good. When the oil circuit is required to be closed, this valve can be used as a one-way locking of the oil circuit to maintain pressure. There are two types of hydraulically controlled One-way valve to control oil leakage: internal leakage and external leakage. The internal drain type can be used in the oil circuit with no back pressure at the oil flow reverse outlet; otherwise, the external drain type is required to reduce the control oil pressure.

2. Check valve is only one type of valve, it can be said that One-way valve is a kind of check valve. The check valve is only a one-way opening and closing valve that prevents the backflow of fluid media on various pipelines or equipment.

There are many types of check valves:

(1) Spring type: the liquid is from bottom to top, relying on the pressure to push up the valve flap controlled by the spring. After the pressure disappears, the spring force will press down the valve flap to seal the liquid back flow. Often used for check valves with small diameters.

(2) Gravity type: similar to the spring type, it relies on the self-gravity of the valve flap to close it to prevent backflow.

(3) Swing type: The liquid flows directly through the valve body, and the rotating disc on one side is opened by the pressure. After the pressure is lost, the disc relies on its own weight to return to the position, and the reverse liquid pressure closes the disc.

(4) Other One-way valve (check valve), such as sewage check valve.

The working principle of one-way valve:

The one-way valve only allows airflow to pass in one direction, and is completely closed in the opposite direction. After the air pressure is added to the left side, the air pressure acting on the valve core overcomes the spring force and friction force to open the valve core, and the air inlet and outlet are connected. The flow of airflow from left to right is called forward flow. In order to ensure a stable flow of air from the air inlet to the air outlet, a certain pressure difference should be maintained between the air inlet and outlet to keep the valve in the open position. If air pressure is added to the air outlet, the air cannot flow in and out, that is, the air flow cannot flow in the reverse direction.

The working principle of the check valve;

Check valve refers to the valve that automatically opens and closes the valve flap depending on the flow of the medium itself to prevent the medium from flowing back. It is also called check valve, one-way valve, reverse flow valve, and back pressure valve. Check valve is a kind of automatic valve, its main function is to prevent the back flow of the medium, prevent the pump and drive motor from reversing, and discharge the container medium. Check valves can also be used to supply pipelines for auxiliary systems whose pressure may rise above the system pressure. Check valves can be divided into swing check valves (rotating according to the center of gravity) and lift check valves (moving along the axis).

The function of this type of valve is to only allow the medium to flow in one direction, and to prevent the flow of direction. Usually this kind of valve works automatically. Under the action of the fluid pressure flowing in one direction, the valve flap opens; when the fluid flows in the opposite direction, the fluid pressure and the self-coincidence of the valve flap act on the valve seat, thereby cutting off the flow.

Related news /products:

The difference between one-way valve and check valve;

The difference between globe valve and check valve;

Introduction of cast steel lift swing check valve(;

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.