The Application of Concentric type Butterfly Valve in Offshore Drilling Platforms

Concentric type butterfly valves find several applications in offshore drilling platforms due to their reliability, compact design, and ease of operation. Here’s how centerline butterfly valves are used in offshore drilling platforms:

- Flow Control in Seawater Systems:

Concentric butterfly valves are used to control the flow of seawater for different purposes:

Cooling Systems: Regulating seawater flow for cooling heat exchangers, engines, and other equipment.

Firewater Systems: Controlling seawater flow for firefighting purposes.

General Service Water: Regulating water flow for various platform operations.

- Fluid Control in Drilling Operations:

Drilling Mud Systems: Controlling the flow of drilling mud during drilling operations.

Mud Mixing Systems: Regulating the flow of chemicals and additives mixed with drilling mud.

- Ballast Systems:

Regulating the flow of seawater into and out of ballast tanks to adjust the platform’s stability and draft.

- Bilge and Drainage Systems:

Managing the discharge of bilge water and other drainage fluids from the platform to maintain a safe environment.

- Fire Protection Systems:

Concentric butterfly valves are used in firewater deluge systems and fire hydrant systems for emergency fire suppression.

- Potable Water Systems:

Regulating the flow of potable water for living quarters, kitchens, and other facilities on the platform.

- HVAC Systems:

Controlling the flow of seawater or chilled water for heating, ventilation, and air conditioning systems.

- Tank Farm Operations:

Handling the flow of various liquids such as crude oil, refined products, and chemicals within the platform’s storage tank systems.

Key Advantages in Offshore Applications:

Corrosion Resistance: Materials are selected to withstand corrosive marine environments.

Space Efficiency: Compact design is suitable for installations where space is limited, which is common in offshore platforms.

Quick Operation: Rapid opening and closing for emergency shutdown situations.

Reliable Sealing: Provides tight shut-off to prevent leaks, crucial for safety and environmental protection.

Safety and Emergency Shutdown Systems:

Concentric butterfly valves are often integrated into safety systems, including emergency shutdown (ESD) systems, to quickly isolate sections of piping in case of emergencies.

Concentric type butterfly valves play a vital role in offshore drilling platforms, ensuring efficient fluid control, safety, and environmental protection. Their versatility, reliability, and space-saving design make them well-suited for various critical applications in offshore oil and gas operations. Proper selection, installation, and maintenance of these valves are essential to ensure the safe and efficient operation of offshore drilling platforms.

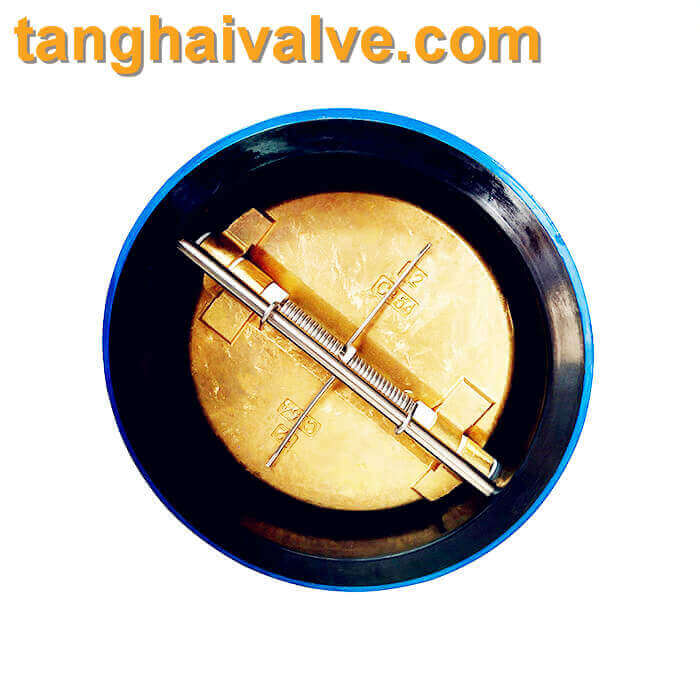

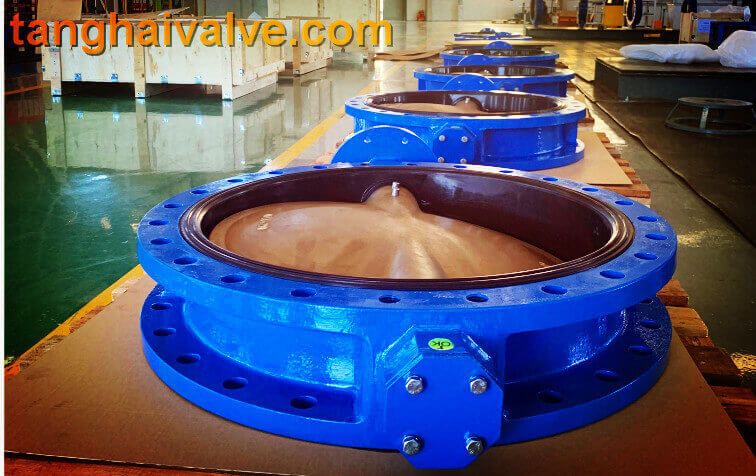

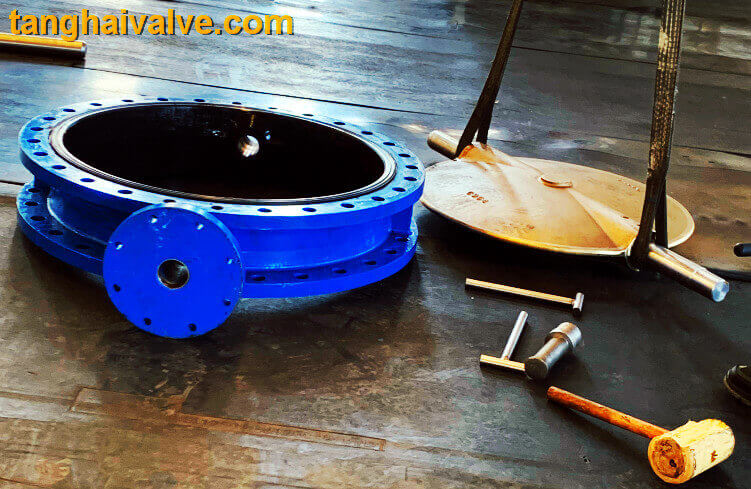

Tianjin Tanghai Valve Co., Ltd. is a professional marine valve manufacturer, including butterfly valve, check valve, gate /Knife gate valve. We have certificates: CE, ISO, BV, DNV foundry and products approval. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services. Below is our wafer butterfly valve of marine valves,if you need to check more information, please click here:https://www.tanghaivalve.com/wafer-type-butterfly-valve-th-btv-aw/.

Please contact us if you need more support, please contact us freely: info@tanghaivalve.com.We are committed to “Build a top valve enterprise; Be a reliable partner!”Friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

Key Features of Double Plate Check Valves

Key Features of Double Plate Check Valves Advantages in Marine Applications

Advantages in Marine Applications

Selection Considerations:

Selection Considerations: Usage:

Usage:

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.