The structure and application fields of the lug type butterfly valve

Product Introduction of lug type butterfly valve:

The driving mode of the lug butterfly valve can be manual, worm gear, pneumatic, electric, hydraulic. The connection method can choose flange and wafer, the

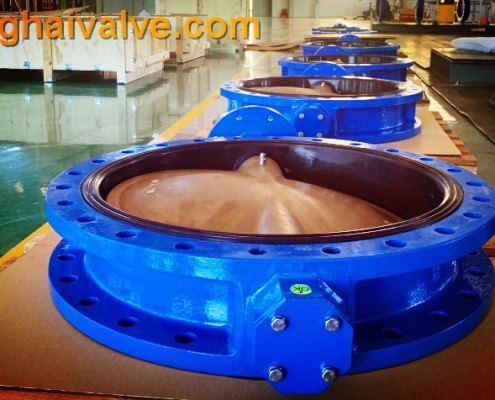

lug type butterfly vlave (15)

structure can choose single eccentric, center line, double eccentric, triple eccentric, and the sealing structure can choose soft seal or hard seal. The pressure range is PN0.1-10Mpa, the nominal diameter is DN40~2000mm, and the material can be cast steel or stainless steel. Due to the wide range of use of valves, the same valve has different combinations in different occasions and working conditions.

The butterfly plate of the lug butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical passage of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0°-90°. When the rotation reaches 90°, the valve is in a fully open state.

Structural features of lug type butterfly valve:

The lug butterfly valve is connected between two pipe flanges with stud bolts. Its structure is simple, small in size, light in weight, and only composed of a few parts. Moreover, it can be opened and closed quickly by rotating 90°, and the operation is simple. At the same time, the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop produced by the valve is small, so it has better flow control characteristics. The butterfly valve has two sealing types: elastic seal and metal seal. Elastic sealing valve, the sealing ring can be embedded in the valve body or attached to the periphery of the butterfly plate.

Application areas of lug type butterfly valve:

Butterfly valves are not only widely used in general industries such as petroleum, gas, chemical, and water treatment, but also used in cooling water systems of thermal power stations.

Used in the gas pipeline in the sulfuric acid industry: the inlet and outlet of the blower in front of the furnace, the inlet and outlet of the relay fan, the electric demisting series and the connecting valve, the inlet and outlet of the S02 main blower, the adjustment of the converter, the inlet and outlet of the preheater, etc. and the use of cut-off gas.

It is used in the sulfur burning, conversion and dry absorption sections of the sulfur-burning sulphuric acid plant. It is the preferred brand of valves for the sulphur-burning sulphuric acid plant. It is regarded by the majority of users as: good sealing performance, light operation, secondary corrosion, high temperature resistance, convenient operation, The flexible, safe and reliable butterfly valve has been widely used.

Lug butterfly valves are also widely used in: SO2, steam, air, gas, ammonia, CO2, oil, water, brine, lye, seawater, nitric acid, hydrochloric acid in the chemical, petrochemical, smelting, pharmaceutical, food and other industries , Sulfuric acid, phosphoric acid and other medium pipelines are used as regulating and shut-off devices.

Tanghai Valve is the best manufacturer of lug type butterfly valve in China. We produce the best quality products with competitive low prices. Maine products: butterfly valve, lug type butterfly valve, wafer type butterfly valve, U-type butterfly valve, double flange butterfly valve, gate valves, check valves, globe valves, valve parts (Valve body, Valve disc, Valve shaft, Valve seat…)

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

related news /knowledge: The main classification method of butterfly valve (2); Uses and characteristics of manual butterfly valve (2); The structural characteristics and uses of the wafer butterfly valve.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.