Marine butterfly valve–Application of Marine Butterfly Valves

Marine butterfly valve is a kind of valve used to control or cut off fluid in liquid or gas flow pipeline on board. The characteristics of marine butterfly valves are simple structure, light weight, convenient operation, and good safety in use. Below, we will introduce marine butterfly valves in several aspects.

1、 Application of Marine Butterfly Valves

Marine butterfly valves are widely used for regulating and cutting off liquid flow and gas in various oil tankers, Chemical tanker, natural gas tankers, liquefied gas tankers and rescue ships. And it can also be applied in other equipment and pipelines, such as petrochemical, energy, metallurgy, power, water treatment and other fields.

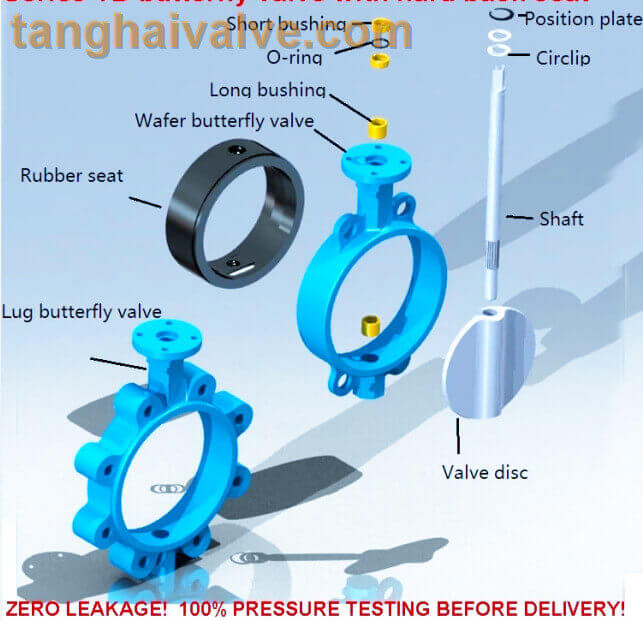

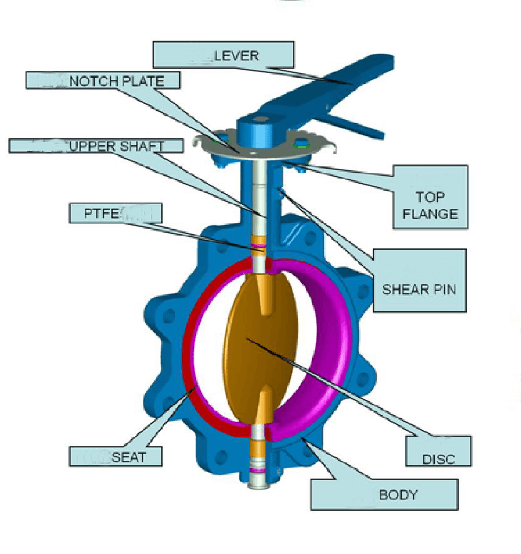

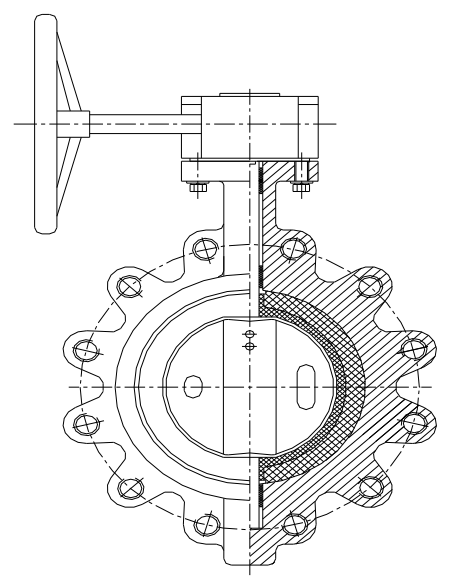

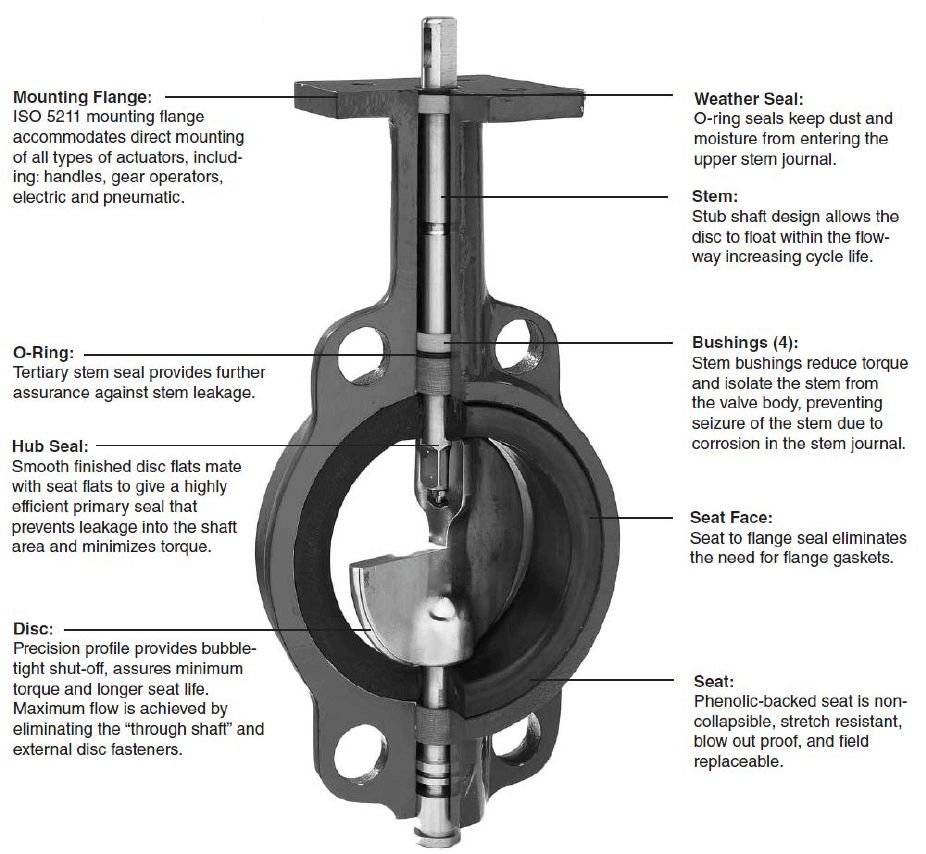

2、 Structure of butterfly valve

Marine butterfly valves generally adopt a circular flat surface on the outside, and are composed of bent plates and closed gaskets on the inside. The valve stem and valve disc are rigidly connected through suitable mechanical connections, and the valve disc is configured into the pipeline to control the flow rate by relying on the flow force itself.

3、 Characteristics of Marine Butterfly Valves

(1)Simple structure, small size, light weight, and low flow resistance.

(2)Quick opening and closing, easy to operate, and reduces fluid switching time.

(3) Corrosion resistance, reliable sealing, and good leak prevention effect.

(4)Long service life and simple maintenance.

(5) Its special structural design ensures that it still retains the advantages of no combustion, leak prevention, and fire resistance under low pressure, small diameter, and critical conditions.

4、 Selection Method of Marine Butterfly Valves

When selecting a marine butterfly valve, it is necessary to consider parameters such as the nominal diameter, pressure rating, mode of action, and medium temperature of the butterfly valve. It is best to make a choice based on specific conditions.

It is necessary to consider the operating temperature and medium characteristics, and appropriate valve diameters and shear forces should be designed based on the flow speed of the medium, and appropriate materials or sealing forms should be selected.

5、 How to Use and Maintain Marine Butterfly Valves

When using marine butterfly valves, attention should be paid to the installation direction and the position of the blocking plate to ensure that the valve is straight and to avoid tilting damage and leakage during operation.

For the maintenance and upkeep of marine butterfly valves, it is necessary to conduct timely inspections, regularly lubricate the valve and its surrounding components, and clean the operating bearings, gaskets, sealing surfaces, and bearings. Special attention should be paid to key areas.

Finally, we need to regularly conduct statistics and analysis on the usage of marine butterfly valves, compare them with other similar equipment, identify problems in the operation of butterfly valves, and promptly handle them. Only by doing well in daily maintenance and paying sufficient attention can the normal operation of butterfly valves be guaranteed and their service life be extended.

Finally, we need to regularly conduct statistics and analysis on the usage of marine butterfly valves, compare them with other similar equipment, identify problems in the operation of butterfly valves, and promptly handle them. Only by doing well in daily maintenance and paying sufficient attention can the normal operation of butterfly valves be guaranteed and their service life be extended.

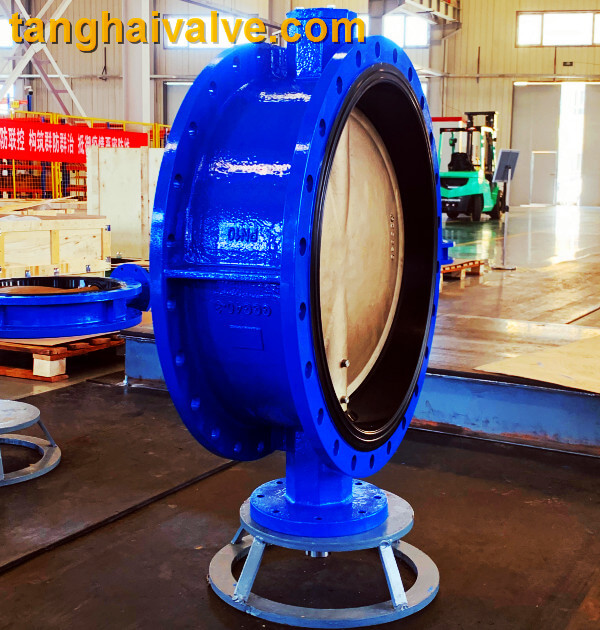

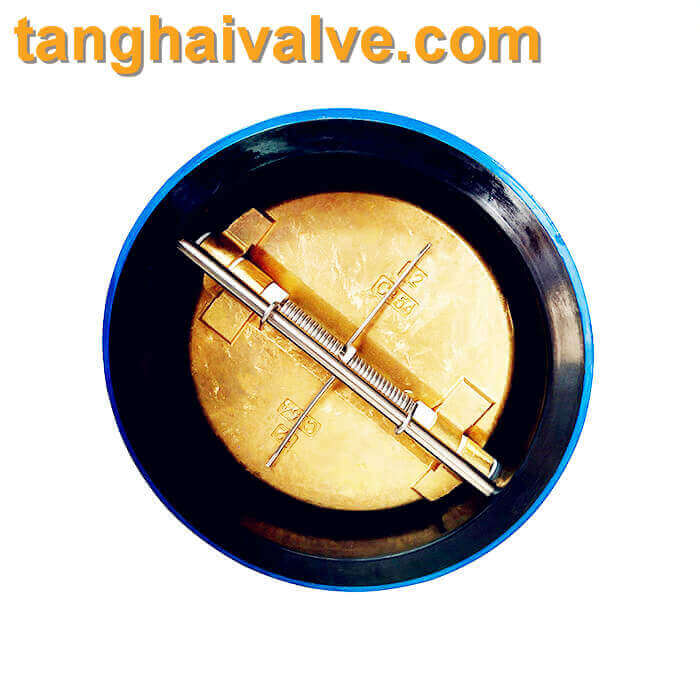

Tianjin Tanghai Valve Co., Ltd. is a professional marine valve manufacturer, including butterfly valve, check valve, gate /Knife gate valve. We have certificates: CE, ISO, BV, DNV foundry andproducts approval. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services.Below is our wafer butterfly valve of marine valves,if you need to check more information,please click here:https://www.tanghaivalve.com/wafer-type-butterfly-valve-th-btv-aw/.Please contact us if you need more support, please contact us freely: info@tanghaivalve.com.We are committed to “Build a top valve enterprise; Be a reliable partner!”

Friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.