How many types of gate valves? gate valve classification

How many kinds of gate valves are there? Which gate valve is suitable for which occasion? How many kinds of gate valves are there?

Commonly used gate valves are as follows:

DIN-F4-BB-NRS-soft seated-wedge gate valve-DN100-PN16-copper holding ring-handwheel (3)

1. Gray iron gate valve: including gray iron open rod gate valve and gray iron dark rod gate valve, this gate valve is suitable for municipal construction, water treatment, water supply and drainage, water conservancy engineering and other fields.

2 ductile iron gate valve: usually for soft seal gate valve, and divided into exposed rod and hidden rod. This kind of gate valve is mainly used in sewage treatment, building fire control, water supply and drainage engineering and other municipal engineering pipeline.

Gray cast iron gate valves and ball valve gate valves are cast iron gate valves. These gate valves are mostly used in normal temperature and low pressure pipelines, and the medium used is mostly water.

3 carbon steel gate valve and stainless steel gate valve: these two kinds of gate valves are used in high temperature and high pressure pipelines, the use of medium for steam, oil and so on. Applications include petroleum, chemical, metallurgy and so on.

4. Knife gate valve: suitable for all kinds of fluid media such as pulp, mud, sewage, powder, syrup, coal pulp, ash, slag-water mixture, etc.

Knife gate valve (6)

The above are just a few common gate valves. In fact, gate valves are not only the above, according to the structure of gate valves, different standards, connection, drive, etc., can be divided into many types.

According to the structure:

1. Implicit stem gate valve: stem nut is placed inside the valve body, in direct contact with the medium, often fixed on the gate. Through the rotation of the stem, the stem nut drives the lubrication plate up and down to complete the opening and closing.

2. Plain stem gate valve: the stem trapezoidal thread is placed outside the valve body, on the upper part of the stem. By rotating stem nut, stem drives gate synchronous rise and fall, realize valve opening and closing, easy to identify the valve. On and off state to avoid misoperation.

3. Flat gate valve: the sealing face is parallel to the vertical center line, so the valve body is parallel to the sealing face on the gate. This valve is the most common type of double gate.

4. Wedge valve: the sealing face is at a certain Angle with the vertical center line, that is, the two sealing faces are wedge valves.

According to different standards: gb gate valve, American standard gate valve, German standard gate valve, Japanese standard gate valve.

According to the connection mode: flange gate valve, welding gate valve, threaded gate valve.

According to the pressure grade: high pressure gate valve, medium pressure gate valve, low pressure gate valve.

According to the driving mode: electric gate valve, pneumatic gate valve, manual gate valve.

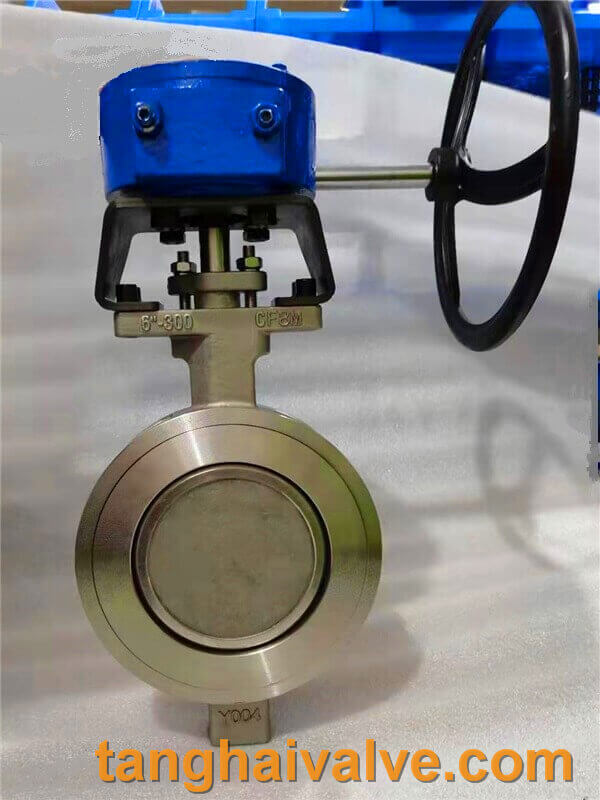

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of knife gate valve:

Video of resilient seated gate valve:

Related news/knowledge:

Pneumatic gate valve model preparation method

The difference between knife gate valve and ordinary gate valve

Valve body and material classification

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.