How does a butterfly valve work?

A butterfly valve is a valve that uses a disc-type opening and closing part to reciprocate around 90° to open, close, or regulate the flow of media. Butterfly valves are not only simple in structure, small in size, light in weight, low in material consumption, small in installation size, small in driving torque, easy in operation and fast, but also can have good flow adjustment function and close sealing characteristics at the same time. One of the fastest valve varieties. Butterfly valves are one of the fastest growing valve varieties in the past decade.

Butterfly valves are widely used. The variety and quantity of its use are still continuing to expand, and develop to high temperature, high pressure, large diameter,

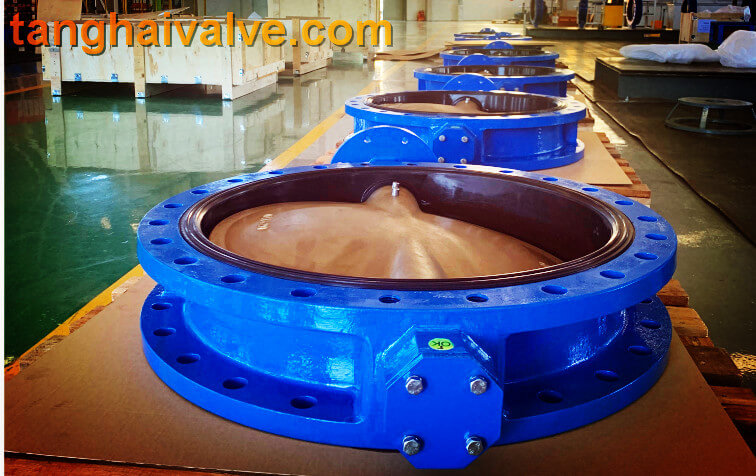

Double flange butterfly valve (16)

high sealing, long life, excellent adjustment characteristics, and multi-function development of one valve. Its reliability and other performance indicators have reached a high level. With the application of chemically resistant synthetic rubber on butterfly valves, the performance of butterfly valves has been improved. Because synthetic rubber has the characteristics of corrosion resistance, erosion resistance, dimensional stability, good resilience, easy forming, and low cost, and can choose different performance synthetic rubber according to different use requirements to meet the working conditions of butterfly valves.

Polytetrafluoroethylene (PTFE) has strong corrosion resistance, stable performance, not easy to aging, low friction coefficient, easy to form, stable in size, and can be filled and added with appropriate materials to improve its comprehensive performance, resulting in better strength and friction coefficient The lower butterfly valve sealing material overcomes the limitations of synthetic rubber. Therefore, polymer polymeric materials represented by PTFE and its filling modified materials have been widely used in butterfly valves. Therefore, the performance of butterfly valves has been further improved, resulting in a wider temperature and pressure range and sealing performance, reliable and longer life butterfly valve.

butterfly valve working diagram-3D GIF animated presentation

In order to meet the requirements of industrial applications such as high and low temperature, strong erosion, and long life, metal seal butterfly valves have been greatly developed. With the application of high temperature resistance, low temperature resistance, strong corrosion resistance, strong erosion resistance, and high strength alloy materials in butterfly valves, metal sealed butterfly valves have been widely used in industrial fields such as high and low temperature, strong erosion, and long life. The emergence of butterfly valves with large diameter (9~750mm), high pressure (42.0MPa) and wide temperature range (-196~606℃) has brought the technology of butterfly valves to a whole new level.

When the butterfly valve is fully opened, it has a small flow resistance. When the opening is between about 15°~70°, the sensitive flow control can be performed, so the application of butterfly valves is very common in the field of large-diameter adjustment. Because the movement of the butterfly plate of the butterfly valve is wiping, most butterfly valves can be used for media with suspended solid particles. Depending on the strength of the seal, it can also be used in powder and granular media. Butterfly valves are suitable for flow regulation. Because the pressure loss of the butterfly valve in the pipe is relatively large, about three times that of the gate valve, when selecting the butterfly valve, the influence of the pressure loss of the pipeline system should be fully considered, and the strength of the butterfly plate to withstand the pressure of the pipeline medium when closing . In addition, the working temperature limit of the elastic seat material must be considered at high temperatures.

The structure length and overall height of the butterfly valve are small, the opening and closing speed is fast, and it has good fluid control characteristics. The structure principle of butterfly valve is most suitable for making large-diameter valve. When the butterfly valve is required for flow control, the most important thing is to correctly select the size and type of the butterfly valve so that it can work properly and effectively. Generally, in throttling, regulating control and mud medium, the structure length is short, the opening and closing speed is fast, and cut off at low pressure (small pressure difference). It is recommended to use a butterfly valve. Butterfly valves can be used when there are two-position adjustment, reduced diameter channels, low noise, cavitation and vaporization, a small amount of leakage into the atmosphere, and abrasive media.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news /knowledges: Introduction of U-shaped flange butterfly valve; The working principle of butterfly valve (picture)

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved. tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com