How to achieve internal and external anti-corrosion of pneumatic valves

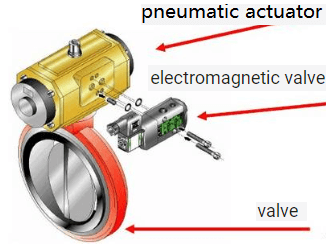

Pneumatic valve using pneumatic actuators, for which Air (or other gas) pressure is the source of power. Air pressure acts on the piston or bellows diaphragm, which produces a linear force on the valve stem. Pneumatic actuator is a kind of Power-operated actuators (using pneumatic, hydraulic or electric power), can remotely adjust valves, or quickly operate large valves.

In order to effectively guarantee the use efficiency of the pneumatic valve, and also to effectively extend the service life of the pneumatic valve, the internal and

Pneumatic actuator (2)

external corrosion protection of the pneumatic valve is a very important part of its use process, then we should pay attention to the main points for the internal and external corrosion protection of the pneumatic valve And what are the main items in the operation, we will give a brief introduction to you in the following article.

1. The inside of the valve body of the pneumatic valve and all parts of the valve plate require comprehensive corrosion protection. On the one hand, it will not rust in water, and there will be no electrochemical corrosion between the two metals; on the other hand, the smooth surface reduces the resistance to water.

2. Hygienic requirements of epoxy resin or paint for anti-corrosion of pneumatic valve body shall have a test report from corresponding authority. The chemical and physical properties should also meet the relevant requirements.

3. The inside and outside of the valve should first be shot blasted to remove sand and rust, and strive to

pneumatic valve structure

electrostatically spray powdered non-toxic epoxy resin with a thickness of more than 0.3mm. When it is difficult to electrostatically spray non-toxic epoxy resin for extra large valves, similar non-toxic epoxy paint should also be brushed and sprayed.

In addition, the pneumatic valve should also pay attention to the necessary maintenance during daily storage and transportation, including:

1. The pneumatic valve should be stored in a dry and ventilated room, and both ends of the passage must be blocked.

2. Valves stored for a long period of time should be checked regularly to remove dirt and apply anti-rust oil on the processed surface.

3. After the pneumatic valve is installed, regular inspections should be carried out. The inspection items are as

D673H-16C-stainless steel pneumatic triple eccentric butterfly valve

follows:

1) The wear of the sealing surface;

2) Trapezoidal thread wear of the stem and stem nut;

3) Whether the packing is out of date and invalid, and if damaged, it should be replaced in time.

TH Valve is one of the largest butterfly valve, check valve manufacturers in China. Now we have our own independent R & D, manufacturing,

assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news /knowledges:

Comparison of pneumatic actuator, electric actuator and hydraulic actuator;

Prevention and treatment of valve corrosion;

Pneumatic ball valve installation instructions;

Pneumatic butterfly valve working principle diagram;

tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved. tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com