How to judge whether the check valve is qualified in the factory pressure test

Check valve refers to the valve that actively opens and closes the valve flap by relying on the activity of the medium itself to avoid the back flow of the medium. It is also called check valve, one-way valve, reverse flow valve, and back pressure valve. The check valve is a kind of active valve whose primary effect is to avoid the back flow of the medium, avoid the reversal of the pump and drive motor, and the discharge of the container medium.

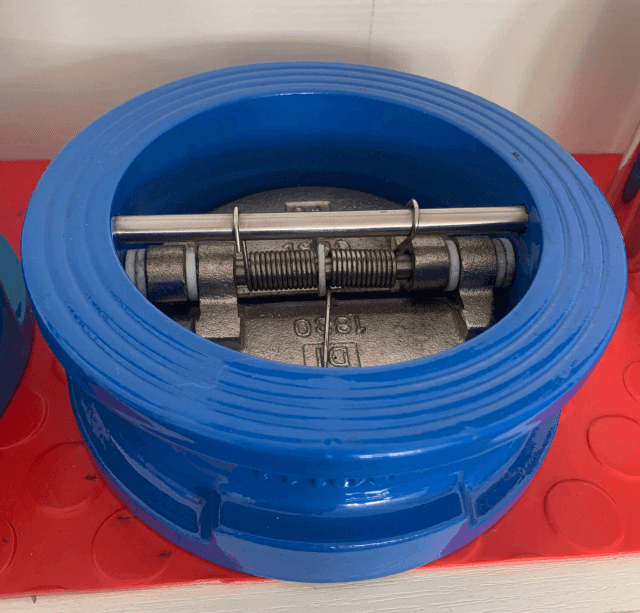

dual plates check valve photos-normal sealing (1)

Check valves can also be used to supply supplementary lines to auxiliary systems whose pressure may rise above the system pressure. The effect of this type of check valve is to only allow the medium to move in one direction and block the movement in the opposite direction. Usually this kind of valve works actively. Under the effect of the fluid pressure moving in one direction, the valve flap opens; when the fluid moves in the opposite direction, the self-coincidence of the fluid pressure and the valve flap will affect the valve seat, and then the movement will be cut off.

Check valves can be divided into swing check valves (rotating according to the center of gravity) and lift check valves (moving along the axis). The swing check valve has a hinge mechanism and a valve disc like a door freely leaning on the surface of the slanted valve seat. In order to ensure that the valve clack can reach the proper position of the valve seat surface every time, the valve clack is designed in a hinge mechanism so that the valve clack can meet the swing space and make the valve clack truly and comprehensively touch the valve seat. The valve clack can be made of metal, or inlaid with leather, rubber, or covered with a composition, depending on the requirements of performance. When the swing check valve is fully opened, the fluid pressure is almost unblocked, so the pressure drop through the valve is relatively small.

The valve disc of the lift check valve is located on the sealing surface of the valve seat on the valve body. Except that the disc can be lifted and lowered freely, the rest of the valve is the same as a shut-off valve. The fluid pressure lifts the disc from the sealing surface of the valve seat, and the backflow of the medium causes the disc to fall back to the seat and cut off the movement. According to the operating conditions, the valve disc can be an all-metal structure, or it can be inlaid with a rubber pad or a rubber ring on the disc holder. Like the stop valve, the passage of fluid through the lift check valve is also narrow, so the pressure drop through the lift check valve is larger than that of the swing check valve, and the flow rate of the swing check valve is restricted. rare.

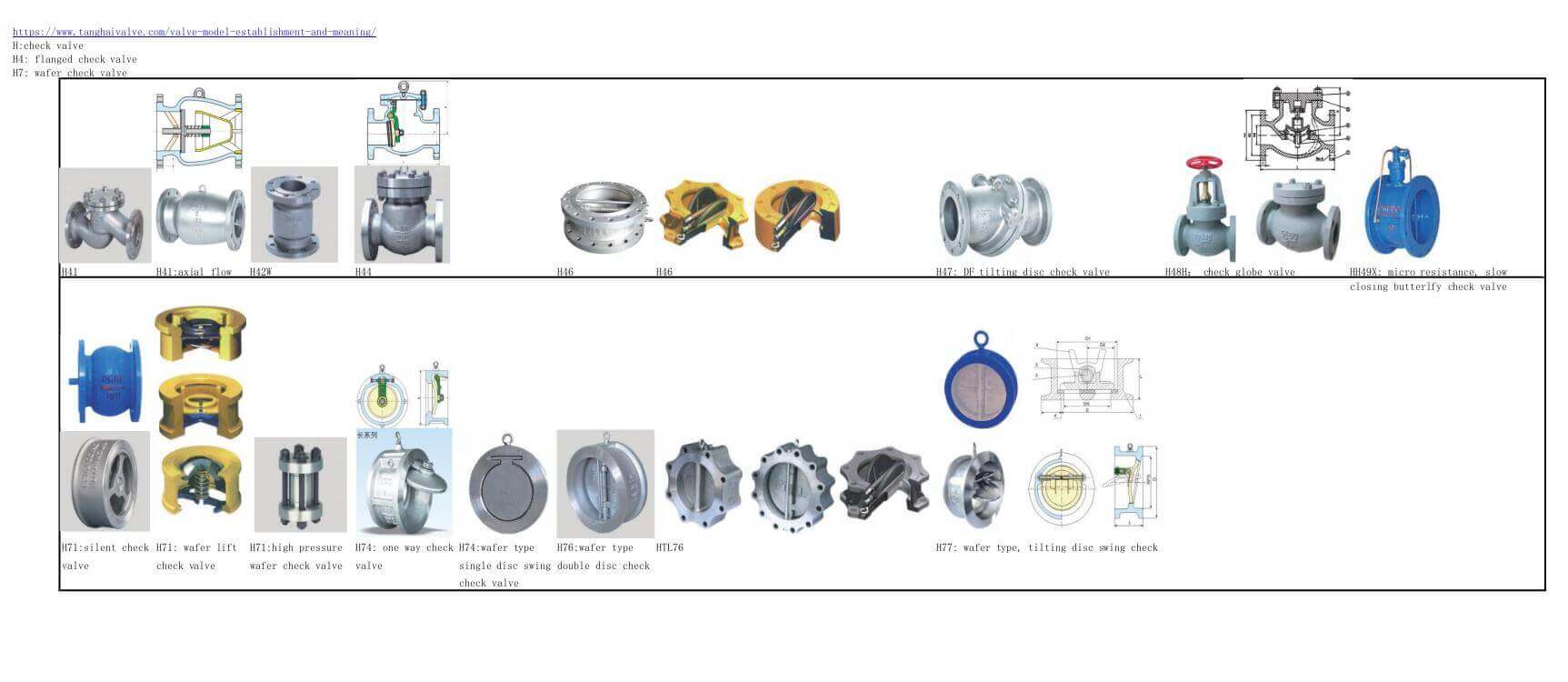

all types of check valve and structures -code names-photos

Check valve experiment status

The flap axis of the lift check valve is in an orientation straight with the horizontal; the channel axis of the swing check valve and the flap axis are in an orientation approximately parallel to the horizontal line.

In the strength test, the test medium is introduced from the inlet end to the specified value, and the other end is closed, and the valve body and bonnet are qualified without leakage.

In the sealing test, the test medium is introduced from the outlet end, and the sealing surface is checked at the inlet end. No leakage at the packing and gasket is qualified.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of dual plate wafer check valve:

Related news/knowledge:

Check valve and its working principle

Introduction of cast steel lift swing check valve

Features of Stainless Steel Valves

All types of check valve and its structures

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved. tanghaivalve.com

tanghaivalve.com