Information about stainless steel wafer butterfly valve

Stainless steel wafer butterfly valves are metal butterfly valves. Metal valves generally have a longer life than elastic sealing valves, but it is difficult to achieve a complete seal. The metal seal can adapt to higher working temperature, while the elastic seal has the defect of being limited by temperature.

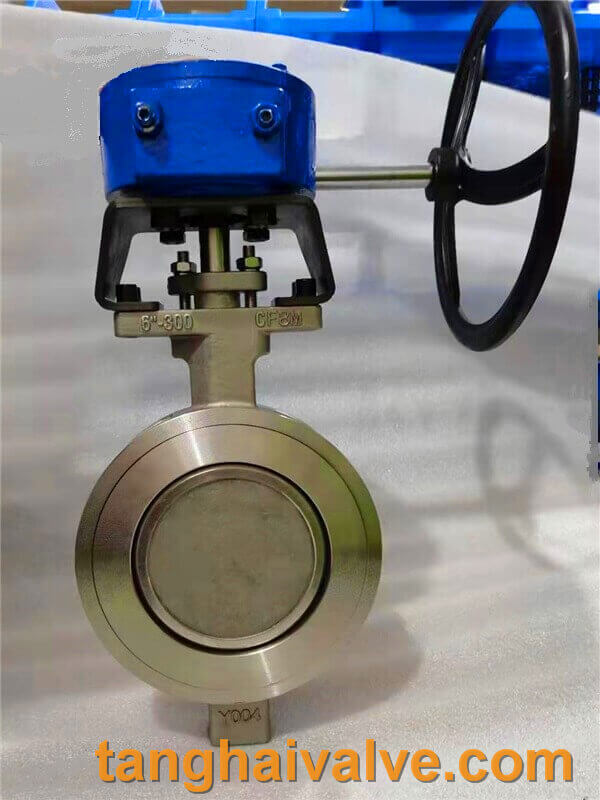

The structure of stainless steel wafer butterfly valve

Double eccentric-wafer butterfly valve-D372F-150lbP-stainless steel (1)

If the butterfly valve is required to be used as a flow control, the main thing is to correctly select the size and type of the valve. The structure principle of the butterfly valve is especially suitable for making large-diameter valves. Stainless steel wafer butterfly valves are not only widely used in general industries such as petroleum, gas, chemical, water treatment, etc., but also used in cooling water systems of thermal power stations. The commonly used wafer butterfly valve uses stud bolts to connect the valve between the two pipeline flanges. The flanged butterfly valve has a flange on the valve, and the two ends of the valve are flanged to the pipeline flange with bolts.

Installation of stainless steel wafer butterfly valve

The butterfly plate of the stainless steel wafer butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical passage of the butterfly valve body, the disc-shaped butterfly plate rotates around the axial direction, and the rotation angle is between 0° and 90°. When the rotation reaches 90°, the valve is in a fully open state. The wafer butterfly valve is simple in structure, small in size and light in weight, and consists of only a few parts. Moreover, it can be opened and closed quickly by rotating 90°, and the operation is simple. At the same time, the valve has good fluid control characteristics. When the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance for the medium to flow through the valve body.

Classification of stainless steel wafer butterfly valves

According to the form, it can be divided into offset plate type, vertical plate type, inclined plate type and lever type. According to the sealing form, it can be divided into two types: soft sealing type and hard sealing type. The soft seal type generally uses a rubber ring seal, and the hard seal type generally uses a metal ring seal. According to the transmission mode, it can be divided into manual, gear transmission, pneumatic, hydraulic and electric.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of center-lined butterfly valve: https://youtu.be/NuSZH_AJcwY

Video of double eccentric butterfly valve: https://youtu.be/yOw2xp3bIaE

Video of triple eccentric butterfly valve: https://youtu.be/AkRwg2X1Wh0

Related news/knowledge:

What is a wafer type butterfly valve

Product Features of Electric Wafer Butterfly Valve

electric wafer butterfly valve vs electric flange butterfly valve

Wafer type double disc swing check valve introduction

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.