Pneumatic ball valve principle, structure and working principle

Principle of Pneumatic Ball Valve|Structure, Principle of Pneumatic Ball Valve

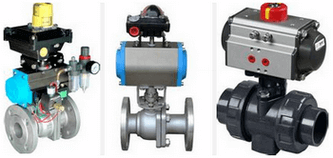

Pneumatic ball valve is a combination of pneumatic actuator and ball valve, instead of manual operation, not only saves a lot of manpower and material resources, but also can control multiple ball valves at the same time. The actuator work of the pneumatic ball valve drives the valve body to open and close quickly, and the speed can achieve the effect of cutting off within seconds. The execution speed of pneumatic actuators is relatively fast, the fastest switching speed is 0.05 seconds/time, so it is usually called pneumatic fast cut-off ball valve.

pneumatic ball valve

The pneumatic actuator of the pneumatic ball valve is mainly divided into single-acting and double-acting. The pneumatic head is equipped with accessories such as triple pieces, positioners, limit switches, etc., which can be used as a throttle to adjust the flow. At the same time, the control box can be added to control the switch in the remote control room.

Working principle of pneumatic ball valve:

The pneumatic ball valve only needs to enter the pneumatic actuator through compressed air, the air source drives the ball core to rotate 0-90 degrees and the small turning torque can control the switch of the ball valve. The valve positioner can be assembled according to the working conditions to control the ball valve. The opening of the core is used to adjust the medium flow. The sphere rotates around the centerline of the valve body to achieve opening, with a circular through hole or channel passing through its axis. When the center of the ball rotates to 90°, the valve is in a tightly closed state. When the actuator is working, the valve can be tightly closed with only a small torque, so that the principle of rapid cut-off can be achieved.

pneumatic V type ball valve

Pneumatic ball valve structure classification:

Pneumatic ball valves can be divided into on-off type pneumatic ball valves and regulating-type pneumatic ball valves according to the difference in structure. The on-off type has only two actions of opening and closing, while the regulating type can control the flow rate!

1. The valve core of the on-off pneumatic ball valve is generally an O-type ball core, and the O-type ball valve spool is a floating precision casting. The diameter of the flow channel is the same as that of the pipeline, and it is mainly used as a cut-off switch.

2. The valve core of the adjustable pneumatic ball valve is a V-shaped ball core, which adopts a fixed structure, with a V-shaped cut on the ball core. Adding a positioner to the actuator can realize the proportion adjustment of fiber-containing and granular media.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved. tanghaivalve.com

tanghaivalve.com