The matching function and principle of pneumatic valve accessories

Pneumatic valve is an actuator that uses compressed air to drive and operate the valve. Its opening and closing speed is relatively fast. It is often used for fast two-position cut-off and can also be used to adjust flow. Because it mainly relies on air to perform operations, so it has high practicability in flammable and explosive situations, and can be used to control gas, liquid, oil, and various corrosive media. However, there are many changes in the accessories in the pneumatic valve. With different accessories, various different control methods can not be achieved. The user can configure the corresponding valve according to the different work needs of the valve.

1. Pneumatic triplex is the most common accessory in pneumatic valves, and its function can be simply summarized

pneumatic valve structure

as: filtration + decompression + oil mist. Among them, the pressure reducing valve is a necessary accessory. The pneumatic valve of any function must be configured. Its function is to give the pneumatic valve a standard power source pressure, the standard value is 0.4-0.7MPa. The pressure reducing valve is a valve that reduces the inlet pressure to a certain required outlet pressure through adjustment, and relies on the energy of the medium itself to automatically maintain a stable outlet pressure. a. The role of the two-piece (filter, pressure reducing valve): complete the filtering and pressure-reducing function of the compressed instrument air b. The role of the three-piece (filter, pressure reducing valve, oil mist device): complete the function of the compressed instrument air Filtering and decompression function, and lubricate the air.

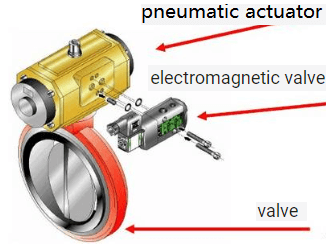

2. The pneumatic solenoid valve can also be called a directional control valve. For two-position valves that only need to be opened and closed, the solenoid valve is a necessary configuration. The solenoid valve achieves the on/off control of the pneumatic valve through excitation/demagnetization. Solenoid valves are often used to switch valves, and control the on and off of the air source and air circuit through voltage signals to control the opening and closing of the valve. Definition: A valve that uses an electromagnet to control the spool movement generally realizes the opening and closing of the valve by controlling the movement process of the pneumatic actuator.

3. The valve limit switch, also called the travel switch, can also be called the echo device. It is a field instrument for

Limit switch-valve

detecting valve status in the automatic control system. It is used to output the open or closed position of the valve as a switch (contact) signal, which is accepted by the program controller or the computer searches for sampling, and executes the next program after confirmation. The product can also be used for interlocking protection of important valves in the system and remote alarm indication. If you want to grasp the valve position status of the two-position valve, the valve limit switch is an effective configuration, which is an electrical switch used to indicate and feedback the limit position of the mechanical equipment.

4. Valve positioner, it is a necessary configuration for pneumatic control valves. The valve positioner can be used to control the position of the valve at any opening degree. It uses the valve stem displacement signal as the input feedback measurement signal and the controller output signal as the setting Signal, compare, when there is a deviation between the two, change its output signal to the actuator, make the actuator act, and establish a one-to-one correspondence between the valve stem displacement times and the controller output signal.

Note: If it is a regulating valve controlled by a safe condition, a solenoid valve must also be configured. The solenoid valve is used to force the valve to be in a safe valve position under unexpected conditions.

For large-capacity cylinder valves, in order to speed up the valve action, the pilot valve must also be configured. The role of the pilot valve is to drive the pilot valve with a small gas signal to switch the atmospheric pipeline, so that the cylinder valve has a better performance. There are many types of pilot valves for fast charging/discharging gas circuits, which should be selected according to the specific needs of pneumatic valves.

If the valve position to be mastered is a regulating valve, a valve opening transmitter must be installed, which can feed back the opening signal of the valve at any position. Due to the requirements of the equipment and technology, the valve may open normally, slowly close, or slowly open, and normally close, then a pneumatic damper is required. The damper is to control the amount of air flow through and adjust to achieve the required valve action speed.

Related products: wafer butterfly valve; lug butterfly valve; double flange butterfly valve;

Double eccentric butterfly valve

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.