Valve material and valve standards-(9)- general valve & parts materials

General valve material

The internal material combination specified by API600 for general valve material:

| Stem material types | hardness | sealing surface | ||

| seal part no., | material type | hardness | ||

| 13Cr | 200-275 | 1 | 13Cr | ≥HB250 |

| 4 | 13Cr | ≥HB750 | ||

| 5 or 5A | HF | ≥HB350 | ||

| 6 | 13Cr/NiCu | ≥HB750/≥HB175 | ||

| 7 | 13Cr/13Cr | ≥HB250/≥HB750 | ||

| 8-8A | 13Cr/HF | ≥HB250/≥HB350 | ||

| 18Cr-8Ni | no require | 2 | 18Cr-8Ni | no require |

| 25Cr-20Ni | 3 | 25Cr-20Ni | ||

| Nickel copper alloy | 9 | Nickel copper alloy | ||

| 11 or 11A | Nickel copper alloy/HF | no require/≥HB350 | ||

| 18Cr-8Ni-Mo | 10 | 18Cr-8Ni-Mo | no require | |

| 12 or 12A | 18Cr-8Ni-Mo/HF | no require/≥HB350 | ||

| 19Cr-29Ni | 13 | 19Cr-29Ni/HF | no require | |

| 14 or 14A | 19Cr-29Ni/HF | no require/≥HB350 | ||

Commonly used valve trim material combination:

| valve stem | sealing surface | valve stem | sealing surface |

| 13Cr | 13Cr/13Cr | 321 | 321/321 |

| 13Cr | 13Cr/STL | 321 | 321/STL |

| 13Cr | STL/STL | 321 | STL/STL |

| 13Cr | 13ZCr/Monel | 1Cr18Ni9Ti | 1Cr18Ni9Ti/1Cr18Ni9Ti |

| 17-4PH | STL/STL | 1Cr18Ni9Ti | 1Cr18Ni9Ti/STL |

| 17-4PH | 17-4PH/17-4PH | 1Cr18Ni9Ti | STL/STL |

| Monel | Monel/Monel | 1Cr18Ni12Mo2Ti | 1Cr18Ni12Mo2Ti/1Cr18Ni12Mo2Ti |

| 304 | 304/304 | 1Cr18Ni12Mo2Ti | 1Cr18Ni12Mo2Ti/STL |

| 304 | 304/STL | 1Cr18Ni12Mo2Ti | STL/STL |

| 304 | STL/STL | 20 Alloy | 20alloy/20alloy |

| 316 | 316/316 | Hastelloy B | Hastelloy B/Hastelloy B |

| 316 | 316/STL | Hastelloy C | Hastelloy C/Hastelloy C |

| 316 | STL/STL | F51 | F51/F51 |

| 304L | 304L/304L | F51 | F51/STL |

| 304L | 304L/STL | 38CrMoALA | STL/STL |

| 304L | STL/STL | 25Cr2MoIV A | STL/STL |

| 316L | 316L/316L | 4Cr10Si2Mo | STL/STL |

| 316L | 316L/STL | 4Cr14Ni14W2Mo | STL/STL |

| 316L | STL/STL | Inconel | Inconel/Inconel |

Commonly used fastener material:

| Bolts | Nuts | Max temp °C |

| 35 | 25 | 425 |

| 35CrMo | 35, 45 | 425 |

| 35CrMo | 30CrMo | 500 |

| 25Cr2MoVA | 30CrMo | 550 |

| 0Cr18Ni9 | 0Cr18Ni9 | 600 |

| 0Cr17Ni12Mo2 | 0Cr17Ni12Mo2 | 600 |

| 25Cr2Mo1VA | 25Cr2Mo1VA | 600 |

| 25Cr2MoVA | 25Cr2MoVA | 600 |

Matching materials of bolts and nuts for American standard valves:

| Bolts | nuts | application temp | ||

| standard | grade name | standard | grade name | |

| ASTM A193 | B7 | ASTM A194 | 2H | -29/425°C |

| B7M | 2HM | -29/425°C NACE standard, anti-sulfer valve | ||

| B16 | 7 | -29/593°C | ||

| B8 | 8 | -196/700°C | ||

| B8M | 8M | |||

| ASTM A320 | L7 | 4 | -46/101°C Cryogenic valve | |

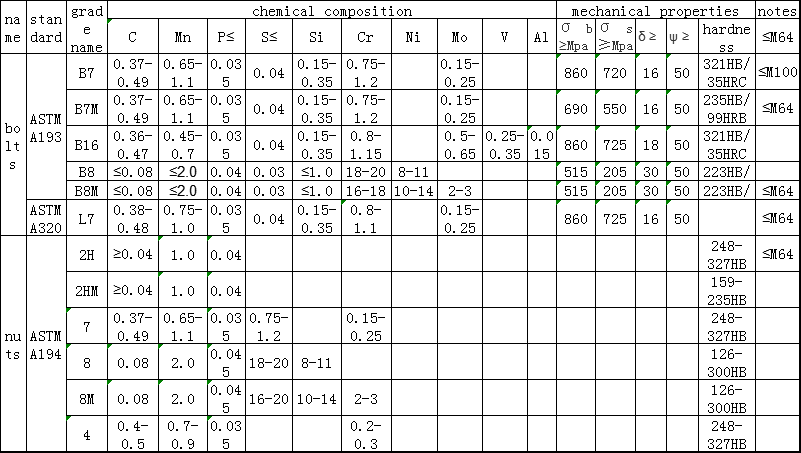

Chemical composition and mechanical properties of commonly used bolts and nuts for American standard valves:

Chemical composition and mechanical properties of commonly used bolts and nuts for American standard valves

Conditions of use of metal gaskets:

| material | HB max | Pressure Mpa(lb) | suitable temp °C |

| 10/08 | 120 | 2.0-42(150-2500) | 450 |

| 0Cr13 | 170 | 2.0-15(150-900) | 540 |

| 0Cr18Ni9 | 160 | 600 | |

| 0Cr17Ni12Mo2 |

Spiral wound gasket service conditions:

| metal belt material | Non-metallic belt material | Pressure grade Mpa (lb) | suitable temp °C |

| 0Cr18Ni9 | flexible graphite | 2.0-26(150-1500) | 650 |

| 0Cr17Ni12Mo2 | flexible graphite | ||

| 00Cr17Ni14Mo2 | PTFE | 200 |

Conditions for use of metal-clad gasket:

| Cladding metal material | HB | filling material | pressure Mpa(lb) | suitable temp °C |

| Al L3 | 40 | asbestos | 2.0-15(150-900) | 200 |

| Co T3 | 60 | 300 | ||

| Galvanized steel sheet | 90 | 400 | ||

| Galvanized steel sheet 08F | ||||

| 0Cr18Ni9 | 187 | 500 | ||

| 00Cr19Ni10 | ||||

| 00Cr17Ni14Mo2 |

Use conditions of flexible graphite composite gasket:

| Core board and edging material | pressure grade Mpa (lb) | suitable temp °C |

| low-carbon steel | 2.0-11(150-600) | 450 |

| 0Cr18Ni9 | 2.0-11(150-600) | 650 |

Non-metallic gasket usage conditions:

| material name | code name | pressure Mpa | suitable temperature °C |

| natural rubber | NR | 2.0 | -50/90 |

| Neoprene | CR | 2.0 | -40/100 |

| NBR | NBR | 2.0 | -30/110 |

| Ethylbenzene rubber | SBR | 2.0 | -30/110 |

| EPDM rubber | EPDM | 2.0 | -40/130 |

| fluororubber | Viton | 2.0 | -50/200 |

| Asbestos Rubber Sheet | XB350 XB450 NY400 | 2.0 ≤300 P.T≤650 Mpa °C | |

| Oil-resistant asbestos rubber sheet | |||

| Modified or filled with PTFE | 5.0 | -196/260 | |

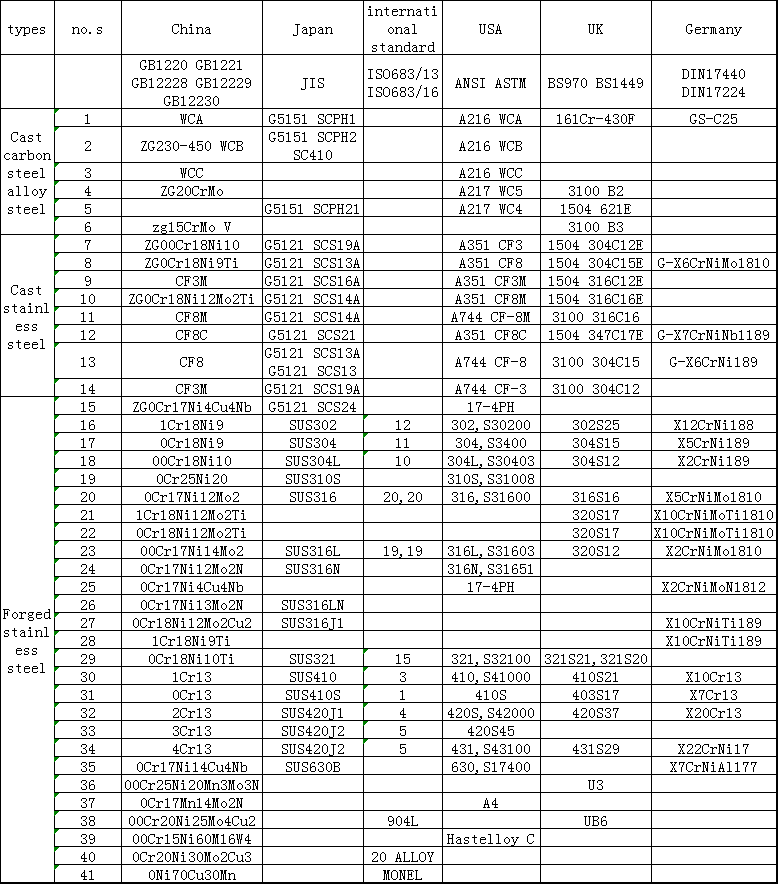

Comparison table of common metal materials specified by Chinese, Japanese, German, British, American and international standards:

Comparison table of common metal materials specified by Chinese, Japanese, German, British, American and international standards

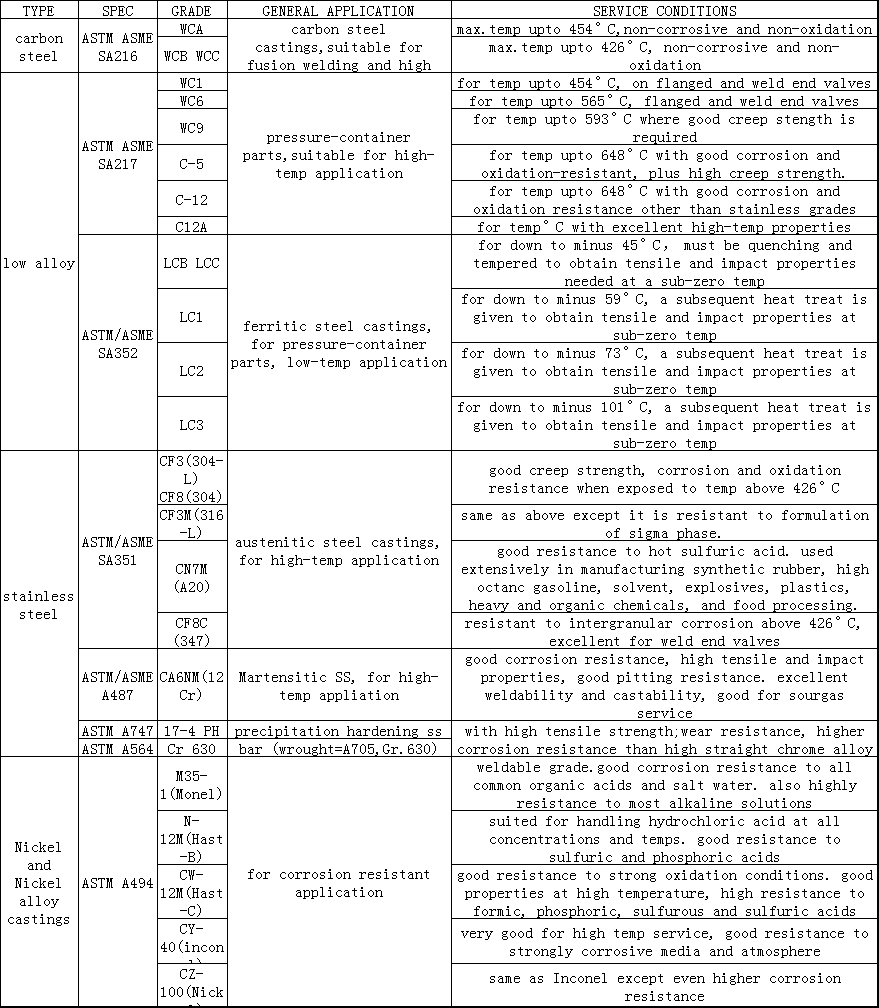

WC carbon steel +A/B/C –WCA,WCB,WCC

WC carbon steel +ABC –WCA,WCB,WCC

Please see the Full documentation at this link: https://www.tanghaivalve.com/wp-content/uploads/2020/09/valve-material-and-valve-standards-Detailed-version.pdf

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news /knowledge:

Valve material and valve standards-(6)-gasket material;

Knife gate valve introduction and its characteristics;

Valve material and valve standards-(2)-body stem bonnet material;

What is the material of Bolts and nuts of Valve Stem?

tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.