Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, DN50 to D1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, ABS, BV, Standards: EN 593, API609

FEEDBACK

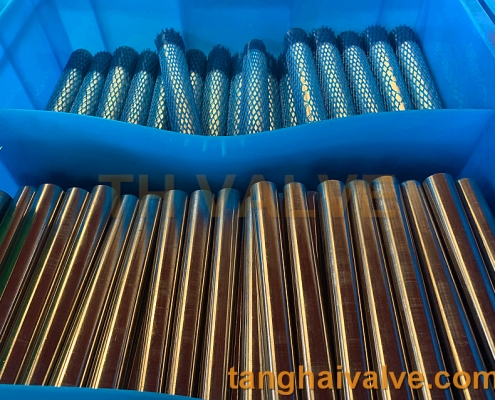

Valve stem shaft (TH-VST)

The valve stem is an important part of the valve, which is used for transmission. It is connected to the actuator or the handle, and the valve core is directly moved or rotated below to achieve the valve switching or adjustment effect.

Features of valve stem shaft

In the process of valve opening and closing, the valve stem is not only a moving part, a stressed part, but also a sealing part. At the same time, it is impacted and corroded by the medium, and also produces friction with the filler. Therefore, when selecting the stem material, it must be ensured that it has sufficient strength, good impact toughness, scratch resistance, and corrosion resistance at the specified temperature. The valve stem is a wearing part, and the mechanical processing performance and heat treatment performance of the material should be paid attention to when selecting.

Common materials

Generally choose 431(16Cr-2Ni), 410 (1Cr13), 420 (2Cr13), F304, F304L, F316, F316L, F321, Inconel 718, Inconel 625, Incoloy825, A105, LF2, Monel 400, Monel 500, F51, F53, F55, 17-4PH ( 630), titanium alloy, XM-19 and other materials.

Common materials and characteristics

- Copper alloy

The commonly used grades are QA19-2 and HPb59-1-1. It is suitable for low pressure valves with nominal pressure less than or equal to 1.6MPa and temperature less than or equal to 200 degrees.

- Carbon steel

A5 and 35 steels are generally selected. After nitriding, they are suitable for ammonia valves with a nominal pressure less than or equal to 2.5 MPa, and low and medium pressure valves for water, steam and other media. A5 steel is suitable for valves whose temperature does not exceed 300 degrees; 35 steel is suitable for valves whose temperature does not exceed 450 degrees. (Note: The actual route proves that the valve stem is made of carbon steel nitrided can not solve the corrosion resistance problem, and should be avoided.)

- Alloy steel

Generally choose 40Cr, 38CrMoA1A, 20CrMo1V1A and other materials. After 40Cr is chrome plated, it is suitable for water, steam, petroleum and other media with a nominal pressure of 32MPa or less and a temperature of 450 degrees or less. 38CrMoA1A is nitrided and can withstand a pressure of 10MPa at a working temperature of 540 degrees. It is often used in power station valves. 20CrMo1V1A can withstand a pressure of 14MPa under the working temperature of 570 degrees after nitriding treatment, and is often used in power station valves.

- Stainless steel

Generally, 2Cr13, 3Cr13, 1Cr17Ni2, 1Cr18Ni12Mo2Ti and other materials are used. 2Cr13 and 3Cr13 stainless steels are suitable for water, steam and weakly corrosive media with a nominal pressure less than or equal to 32MPa and a temperature less than or equal to 450 degrees. The surface can be strengthened by chrome plating, high frequency quenching and other methods. 1Cr17Ni2 stainless steel valve and cryogenic valve are resistant to corrosive media. 1Cr18Ni9Ti, 1Cr18Ni12Mo2Ti stainless acid-resistant steel is used in high-temperature valves with a nominal pressure of 6.4MPa or less and a temperature of 600 degrees or less, and can also be used in stainless steel valves and cryogenic valves with a temperature of -100 degrees or less. 1Cr18Ni9Ti is resistant to corrosive media such as nitric acid; 1Cr18Ni12Mo2Ti is resistant to corrosive media such as acetic acid. When 1Cr18Ni9Ti and 1Cr18Ni12Mo2Ti are used in high-temperature valves, nitriding treatment can be used to improve scratch resistance.

- Bearing chrome steel

Select GCr15, suitable for ultra-high pressure valve with nominal pressure less than or equal to 300MPa and temperature less than or equal to 300 degrees.

There are many materials used to make the stem, there are 4Cr10Si2Mo martensitic heat-resistant steel, 4Cr14Ni14W2Mo austenitic heat-resistant steel, etc.

The stem nut and the stem are threaded to directly bear the axial force of the stem, and the friction between the brand and the bracket and other valve parts. Therefore, in addition to a certain strength, the valve stem nut also needs to have the properties of small friction coefficient, no rust, and no biting with the valve stem.

Valve stem manufacturing process

The head of the round bar material is upset to manufacture the valve stem blank, and the valve stem is heated, heat-preserved, quenched, tempered, normalized, secondary tempered, solution treated, and aged. After turning and forming, the thread part is cold-pressed by a thread rolling machine. The milling machine processes the T-slot (flat) of the valve stem end and head. The grinder processes the roughness of the product. At the junction of the valve stem and the ball, the valve stem and the valve There should be an anti-static mechanism at the body contact to prevent static electricity from accumulating on the sphere.

tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved. tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com